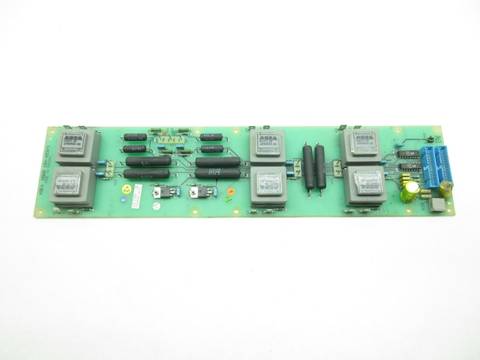

AMAT 0041-48723

Understanding AMAT 0041-48723: A Key Component in Electrical Engineering

At AE Automation System Parts, we specialize in integrated industrial system solutions that drive innovation and efficiency across various sectors. One of the essential components we focus on is the AMAT 0041-48723, a crucial part in the realm of electrical engineering.

Importance of AMAT 0041-48723 in Electrical Engineering

The AMAT 0041-48723 serves as a vital element in electrical circuits, enabling reliable and efficient performance. Its design adheres to stringent standards, ensuring safety and durability in various applications. Understanding its importance in electrical engineering is not just about its functionality; it’s about how it enhances system performance and reliability in critical operations.

Technical Specifications According to IEC60947-2

The AMAT 0041-48723 complies with the International Electrotechnical Commission (IEC) standard IEC60947-2, which outlines the safety requirements for low-voltage switchgear and control gear. This adherence ensures that the component can operate safely and effectively under various conditions. Key specifications include:

- Rated Voltage: The component is designed for a maximum operational voltage range that ensures compatibility with most industrial applications.

- Current Rating: The AMAT 0041-48723 supports various current ratings, making it versatile for different electrical loads.

- Insulation Class: It features superior insulation properties that prevent electrical failures and enhance safety.

- Temperature Range: The component operates effectively across a wide temperature range, ensuring performance stability in diverse environments.

Applications in Industrial Automation

The AMAT 0041-48723 is widely utilized in industrial automation systems. Its capabilities enable control and monitoring of equipment, contributing significantly to efficiency and productivity. Key applications include:

- Motor Control Centers: It is used in motor control applications to provide efficient control of electric motors.

- Process Automation: The component is integral in automation systems that enhance production processes in manufacturing plants.

- Safety Systems: The AMAT 0041-48723 plays a role in safety interlock systems, ensuring the safe operation of machinery.

Renewable Energy Applications

As the world moves towards sustainable energy solutions, the significance of the AMAT 0041-48723 in renewable energy systems cannot be understated. Its reliable performance supports:

- Solar Energy Systems: The component is essential in solar inverters, enabling efficient conversion of solar energy into usable electrical energy.

- Wind Energy Systems: It is also used in wind turbine control systems, ensuring optimized performance and energy generation.

Conclusion

The AMAT 0041-48723 stands as a testament to the advancements in electrical engineering, providing solutions that enhance both industrial automation and renewable energy applications. By adhering to IEC60947-2 standards, it guarantees safety and efficiency, making it a crucial component in modern engineering practices.

For more information on this and other essential components in industrial automation, visit our internal link, and to explore further industry standards, check out the International Electrotechnical Commission (IEC).